Elevator Lifts

These lifts use elevator carts to lift one or multiple balls up a shaft, with the use of pulleys or cranks. If using pulleys with chain or string, there needs to be some mechanism to make it go in two directions, reversing when the cart gets to the top and bottom. This was first done with my forward/reverse transmission (instructions of just the transmission can be found here), but there are other ways as can be seen below. The most reliable and balanced methods are the transmission and reversing chain. The lifts below are mainly categorized by their directional methods, with the concepts of the shaft (whether vertical or curved) and cart being similar on all of them.

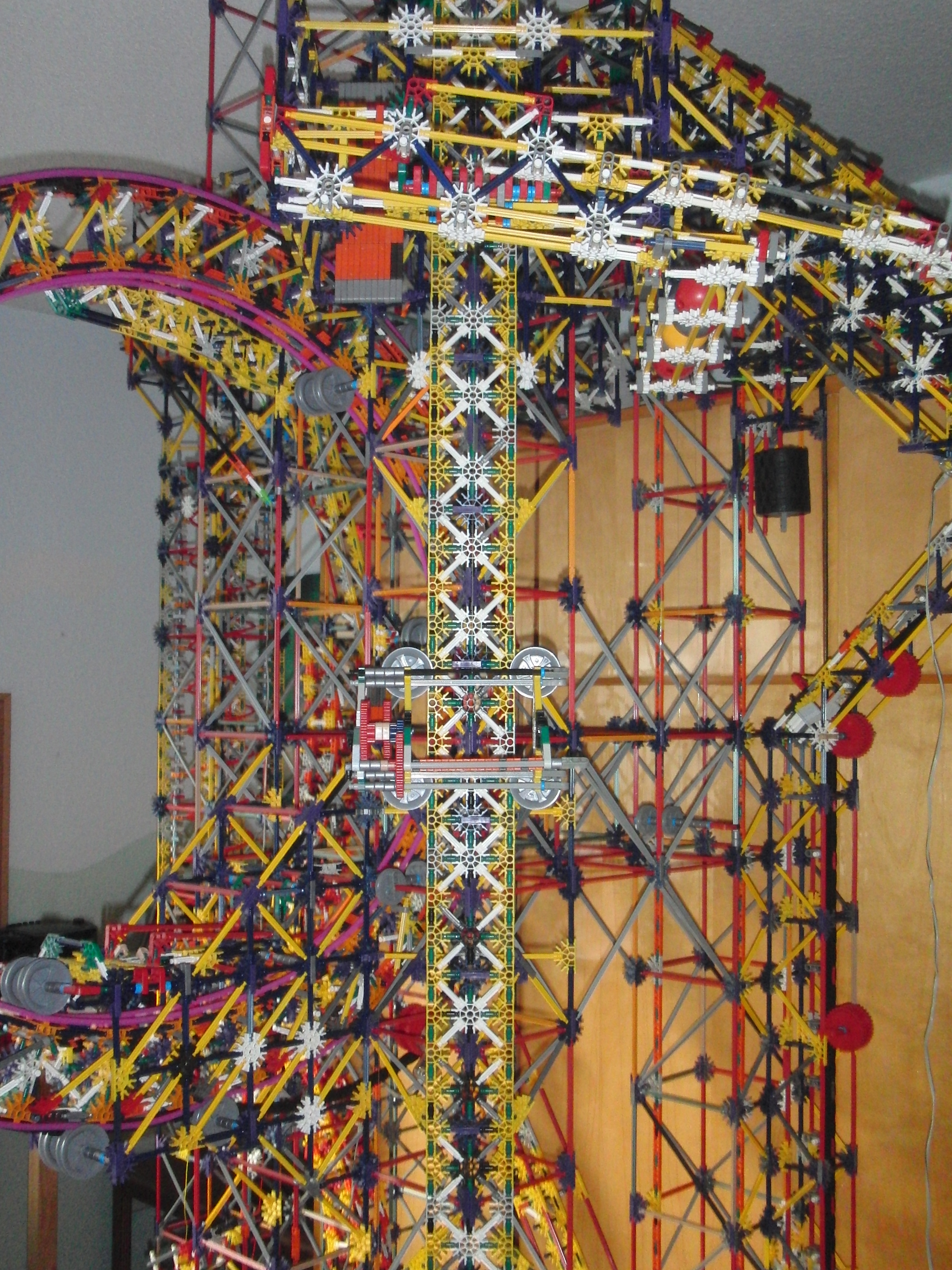

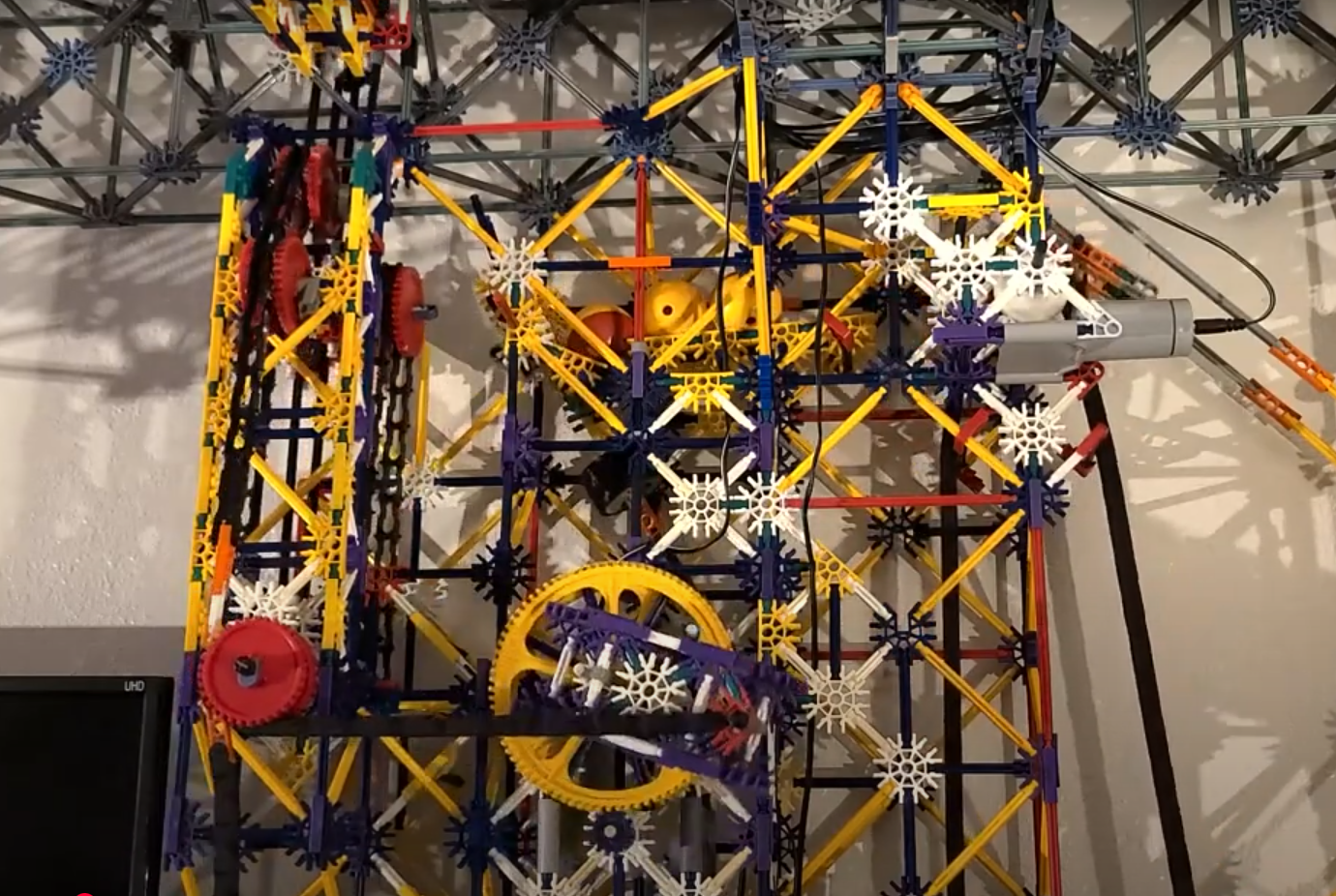

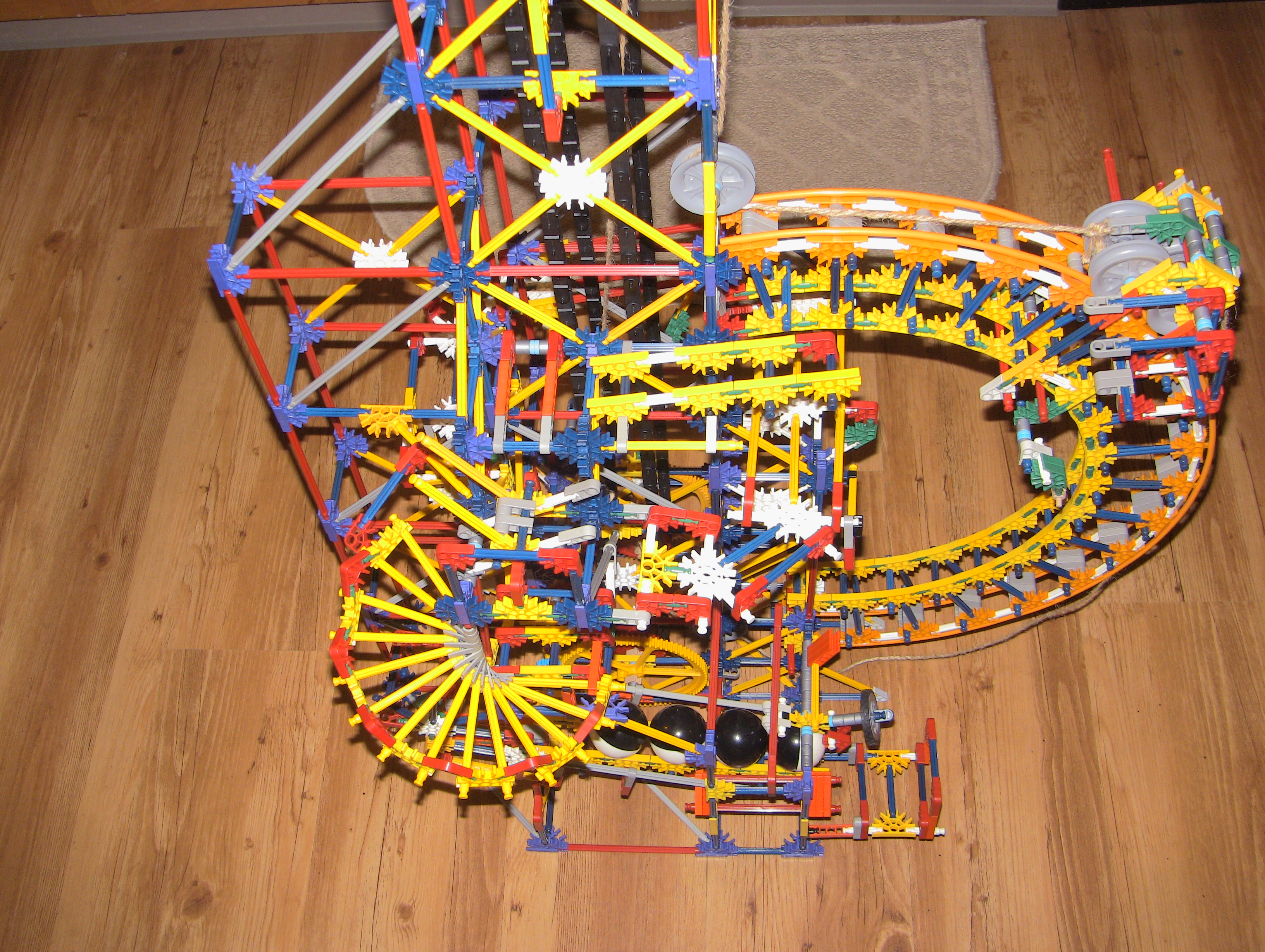

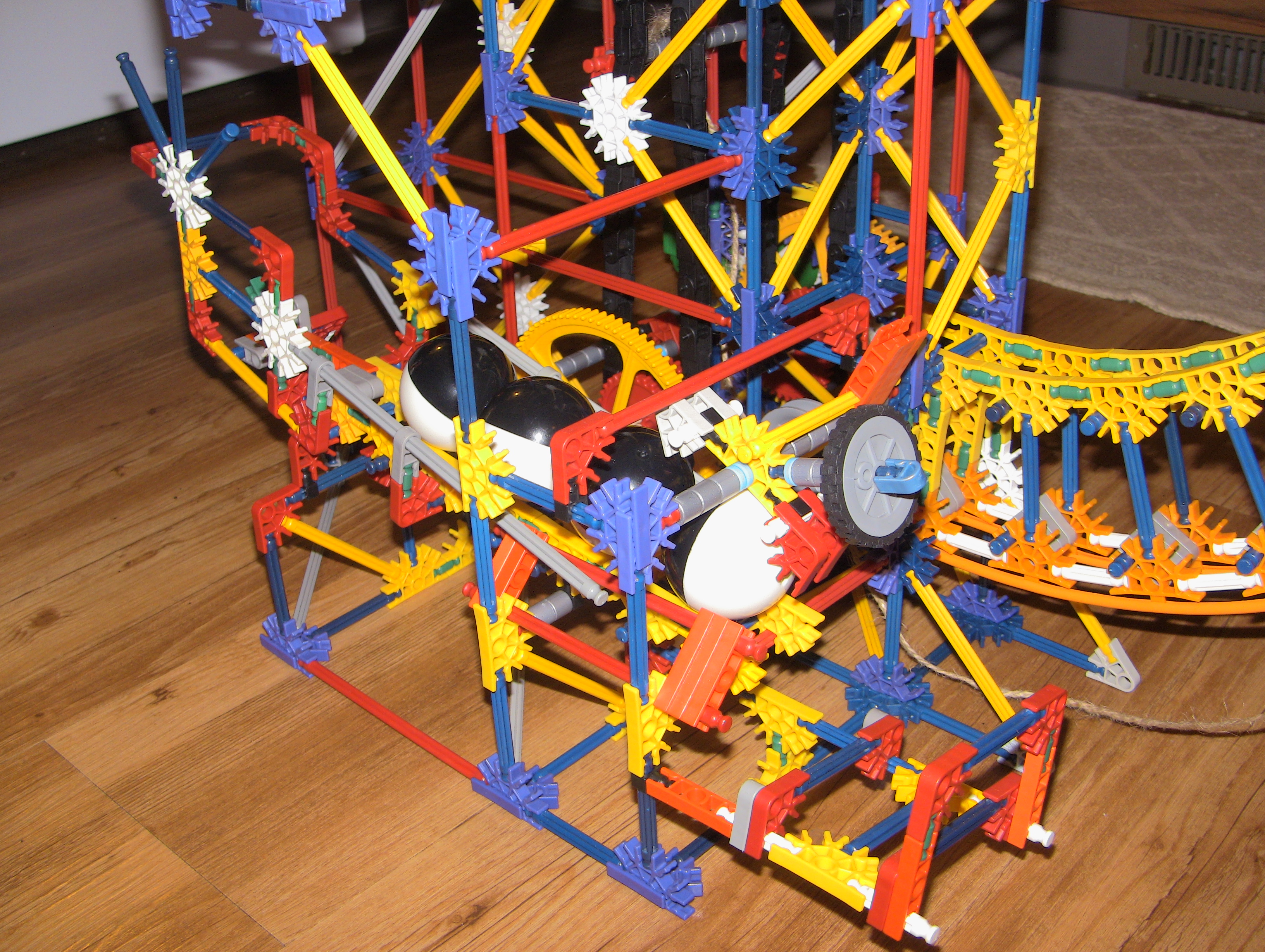

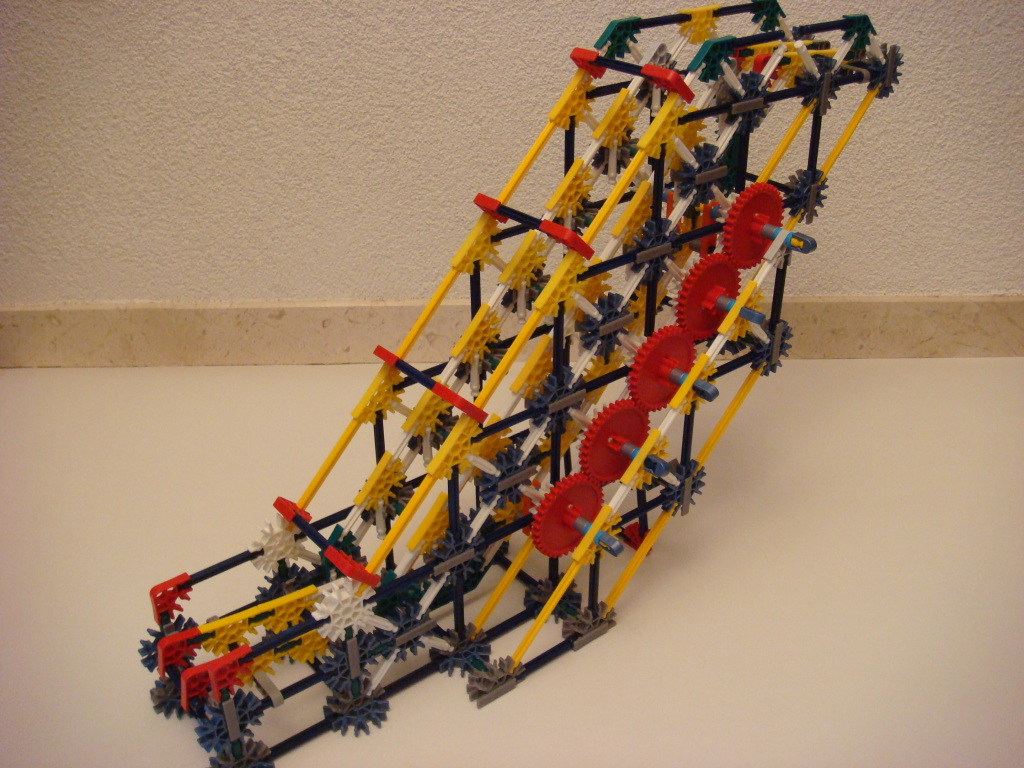

Transmission Elevator Lift

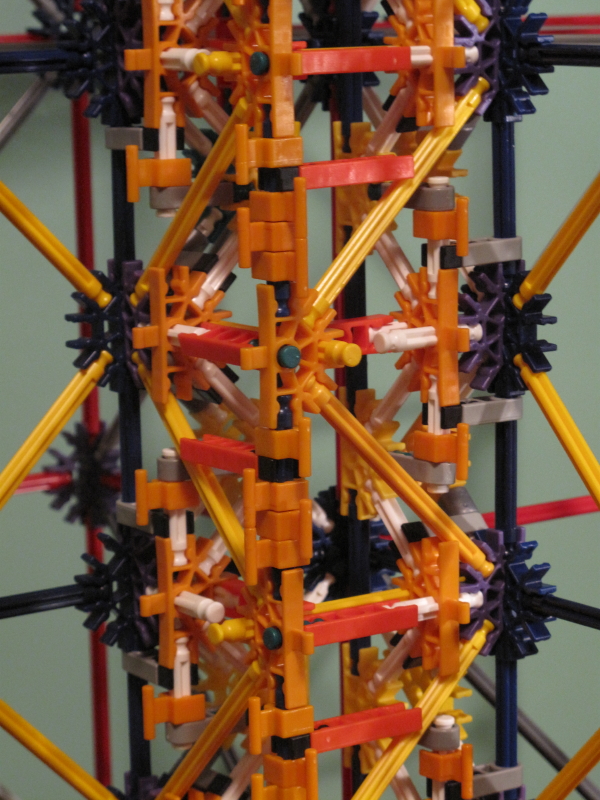

Most elevator lifts use a forward/reverse transmission to control the up and down motion of the elevator cart. This causes a constant and predictable motion, unlike other methods such as cranks. It’s more efficient to have the elevators have two carts; one balances the other out, not needing a counterweight and the lift has double capacity. The first one made for Citadel uses two carts to lift the balls, each one carrying 4 balls. The transmission gearbox is located in the base which makes adjustments easier. There are two reels of fishing line, and the reels are easy to adjust, which helps to combat stretching of the fishing line. This lift runs smoother and faster than other designs, but it uses tubing and the layout of the carts means a complex shaft with orange-tabbed connectors and splicers. It’s easier to make the shafts lined up with each other, or perhaps even on different areas in the ball machine.

A simpler version that uses less pieces and no tubing was made by dickheijboer. The carts each hold 3 balls and the transmission is at the top. It also uses chain which is easier to set up. Plus, this version has instructions.

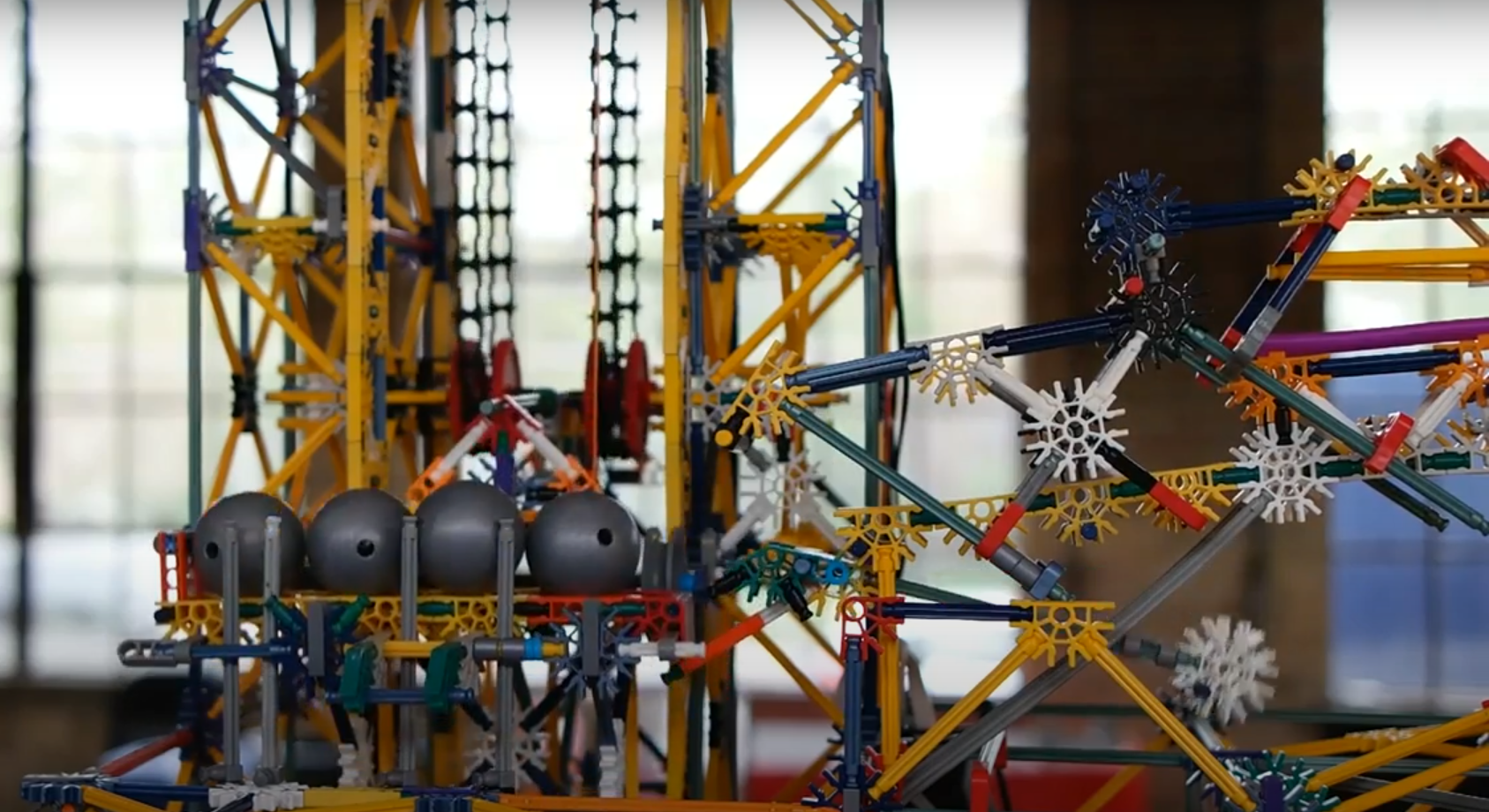

Single Elevator Lift

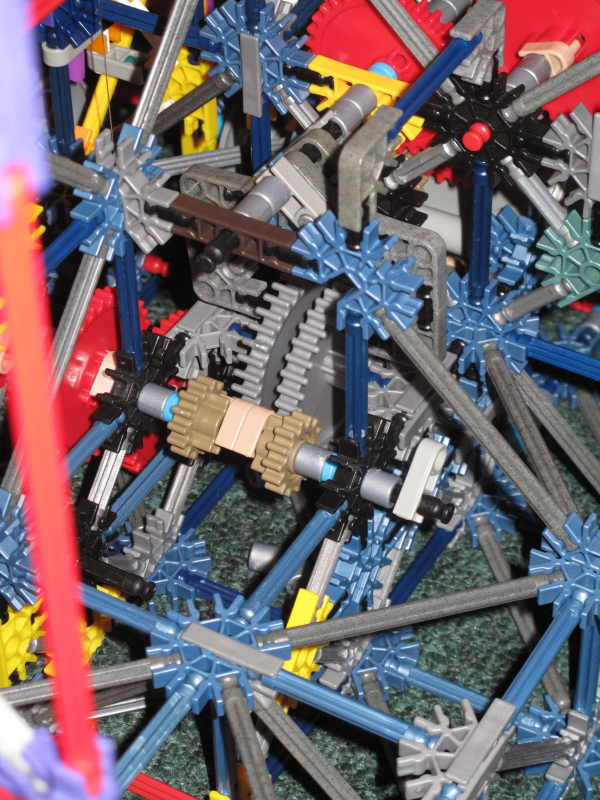

These use a single cart on one end of a pulley system and a counterweight on the other. Sorunome’s version uses an elevator cart that holds 8 balls. The up and down motion is controlled by a gearbox that has forward and reverse transmission, similar to the twin elevator lift. Levers switch the gearbox when the elevator gets to the top/bottom. In total, the lift uses 34 gears. This version doesn’t need tubing like some other designs.

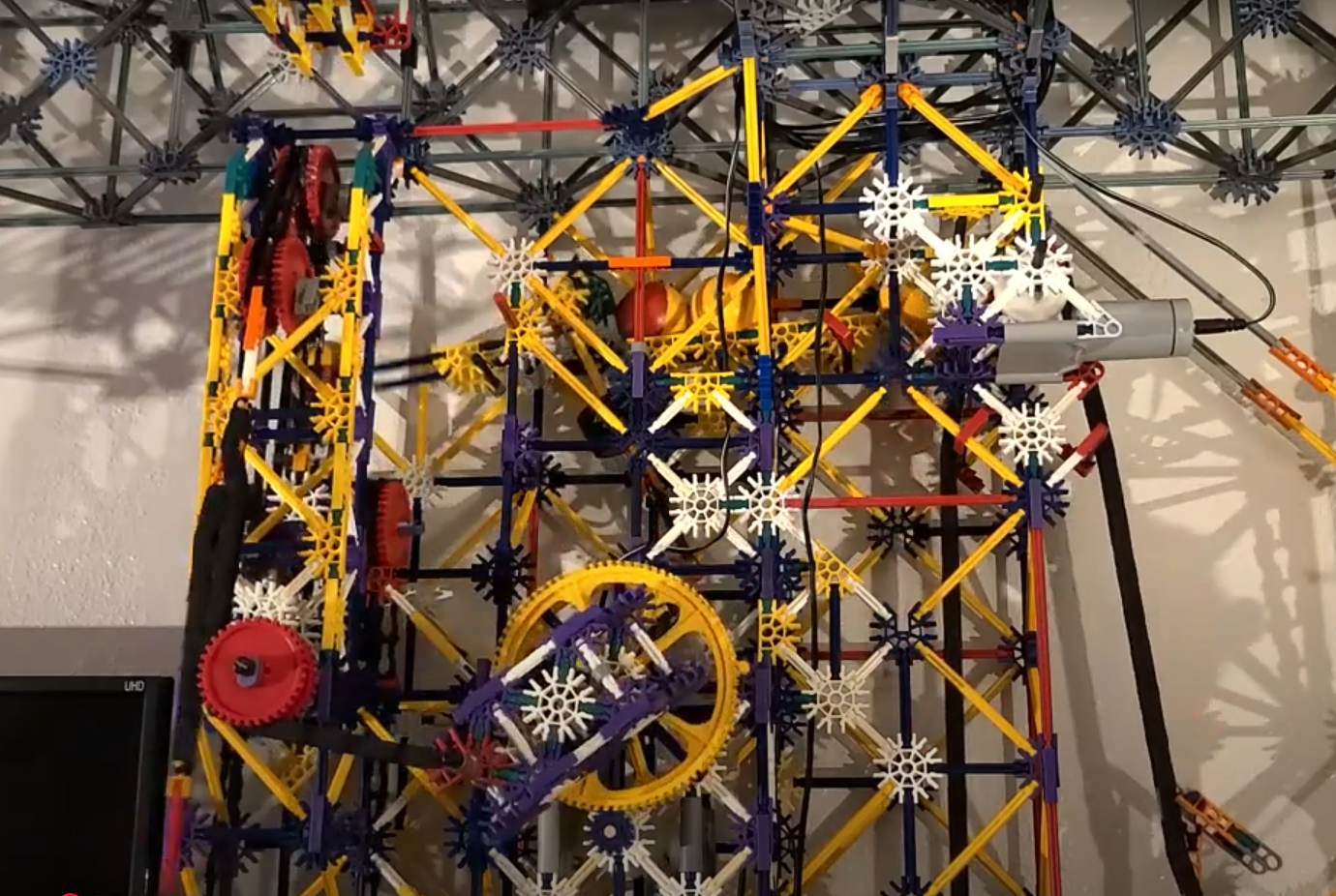

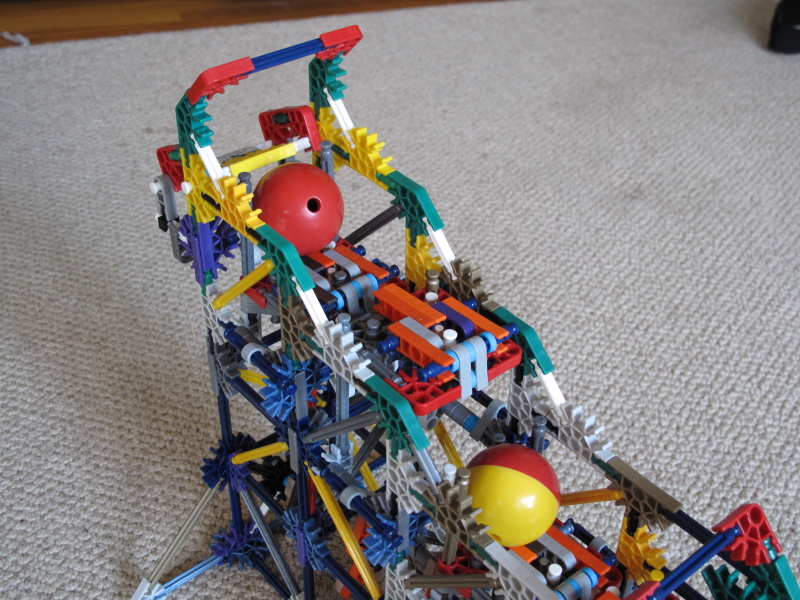

Elevator Freefall Lift

This lift uses a different mechanism to change directions. It uses a special gear to lift the pulley, and at the top disengages and sends the cart falling back down. The only issues are a crown gear needs some teeth cut off, and it will be slightly off balance if adding a counterweight, since the cart needs to be heavier even without balls so it falls down correctly.

Crankavator

These use a crank to lift and change the direction of the elevator cart. They can be large cranks, like in the original version in Tartarus, or they can be smaller like mathsboy314’s version. The larger it gets, the more complex the drive system will be since it needs a lot of torque.

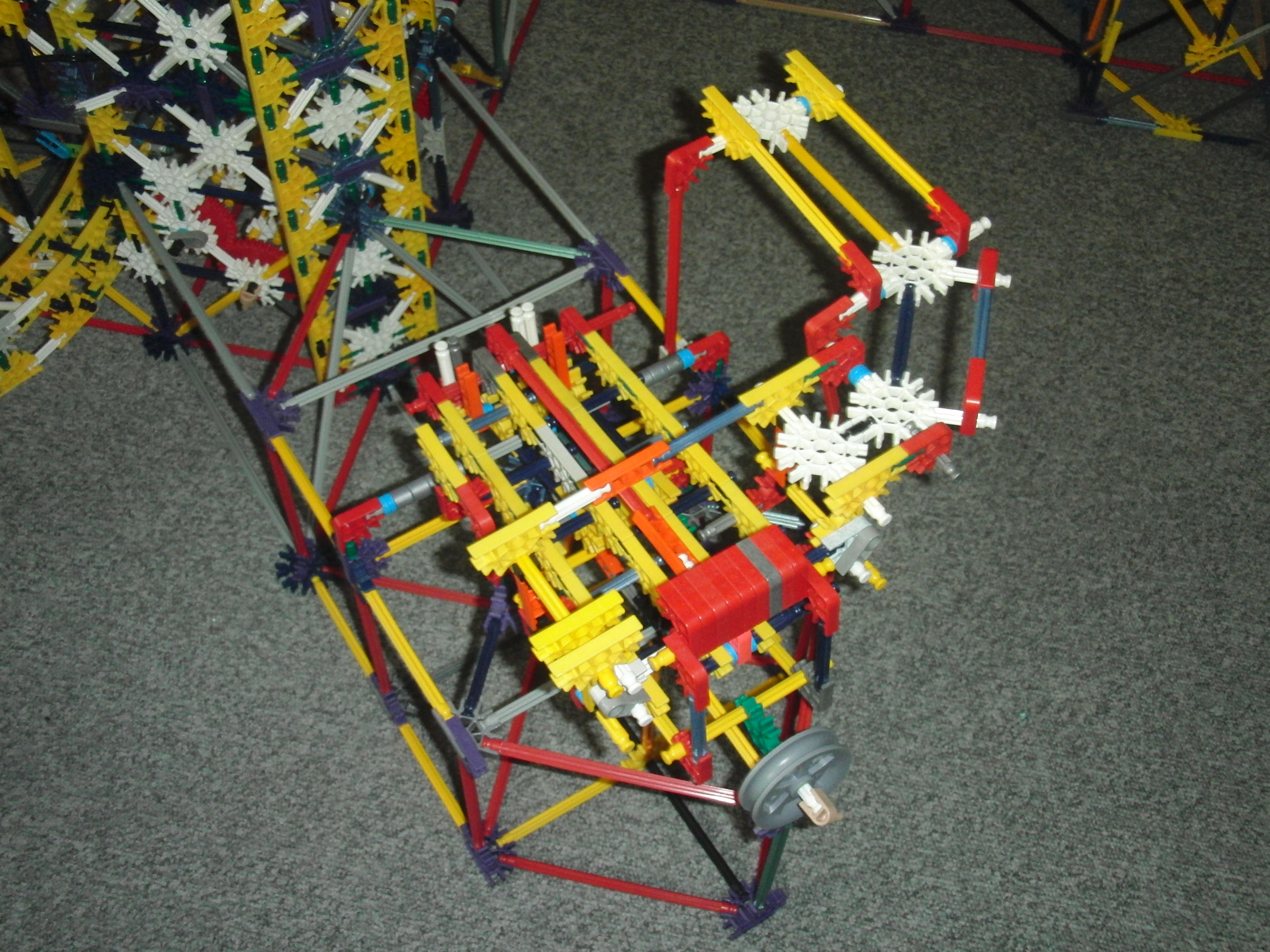

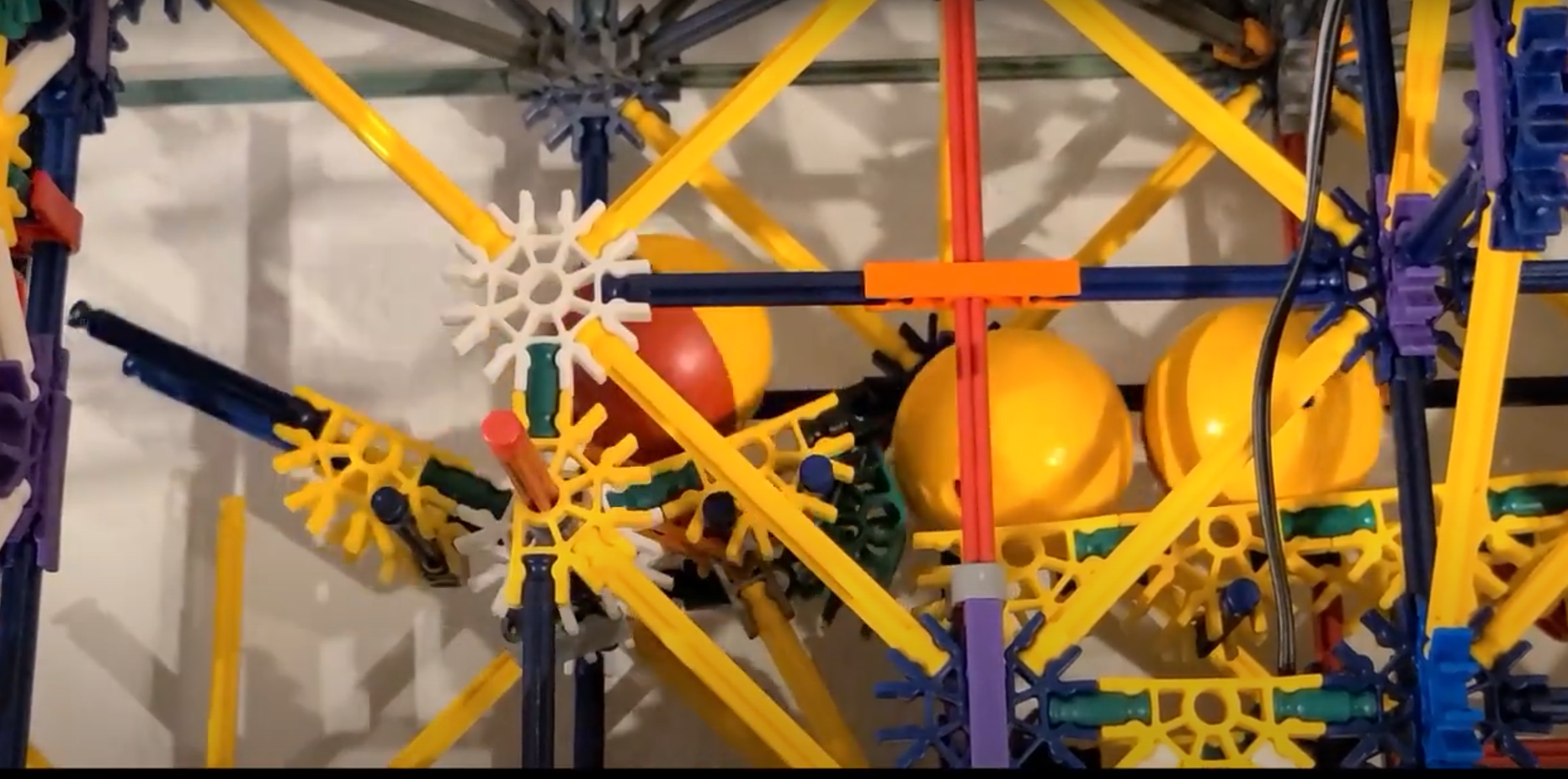

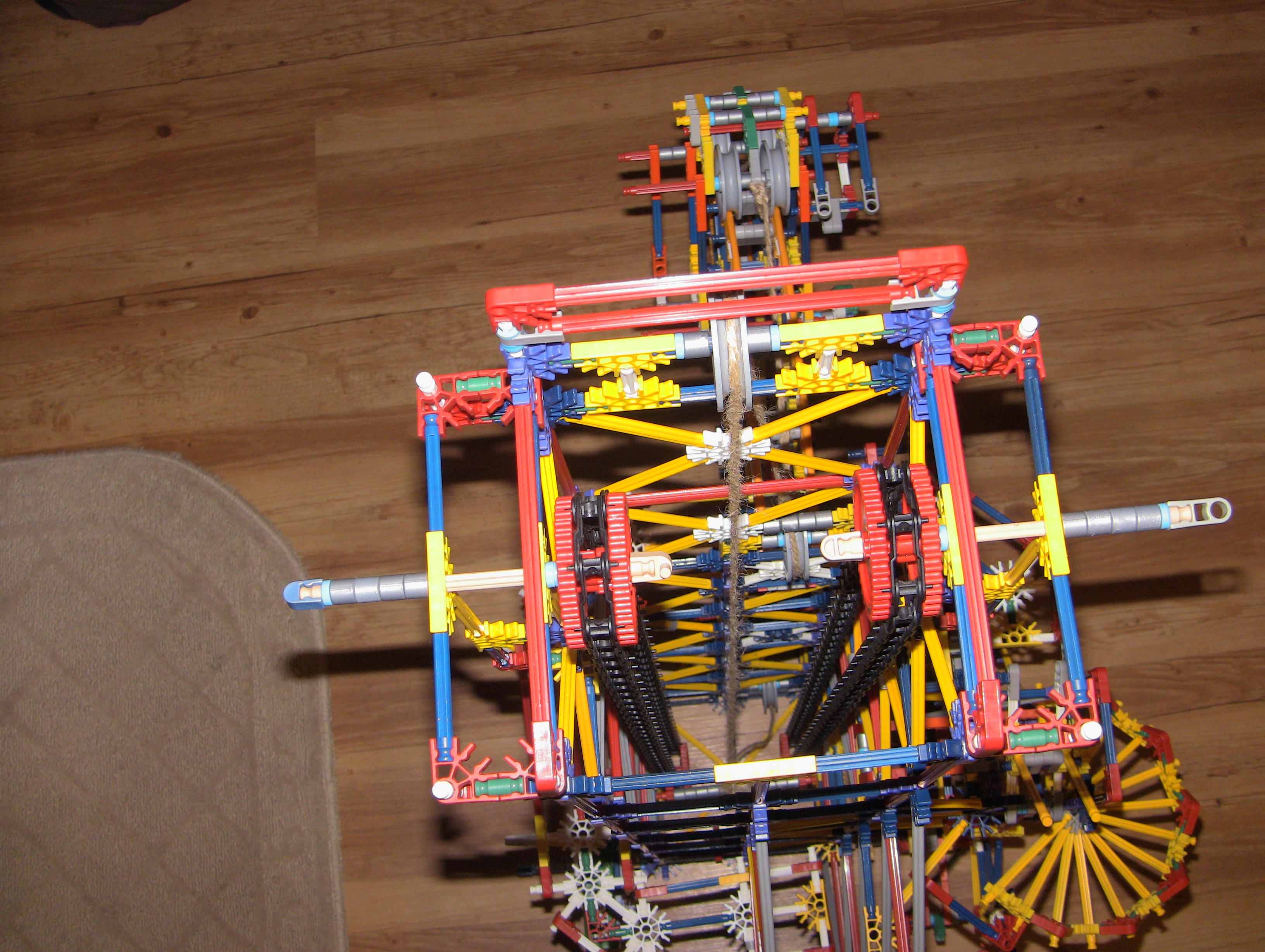

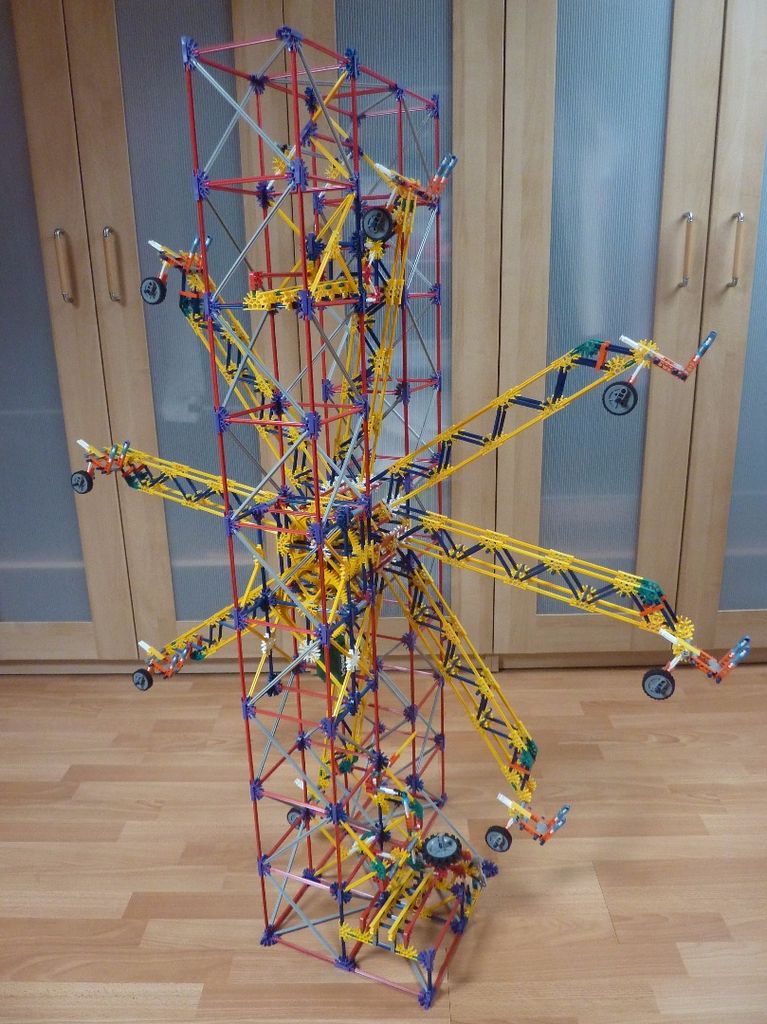

Telescopic Elevator Lift

This elevator uses a crank and chain/string similar to a crankavator, except there are two stages of sliders where the movement of the first stage causes the second stage, mounted onto the first, to move up the same distance. This doubles the travel distance of the elevator cart with less space being used up. This particular version is also designed to get the ball up right next to the ceiling, which isn’t very common with other lifts. The crank design is also designed to save space, using a custom-made roller bearing to support just one crank arm, rather than the typical two crank arms on either side.

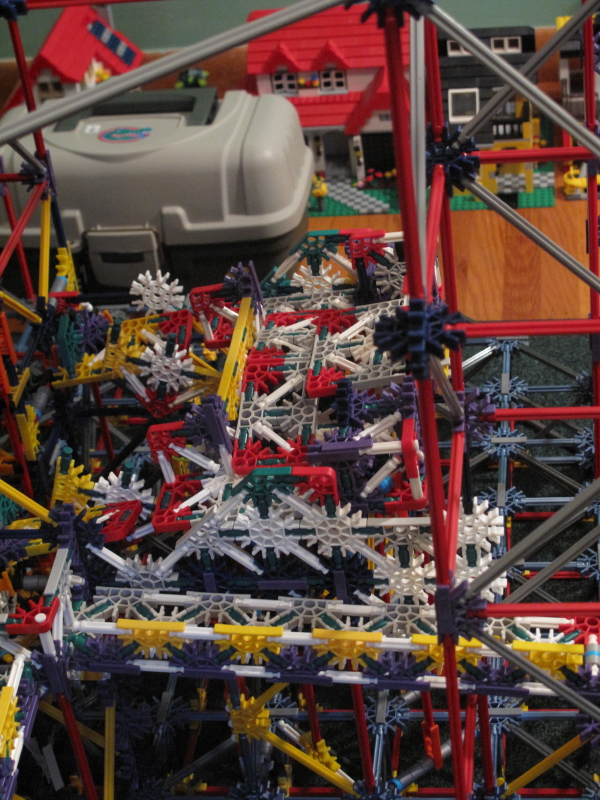

This lift could also use more than two stages, if the sliders are made strong enough. The distance traveled by the ball can be multiplied by however many stages there are. The last image shows a prototype lift I made in 2011, but it’s recommended to keep the stages as small and light as possible. This version would have used string and had a cart to hold four balls. The exit track can be tilting like this one or let out like in Austron’s when it leaves the black rails.

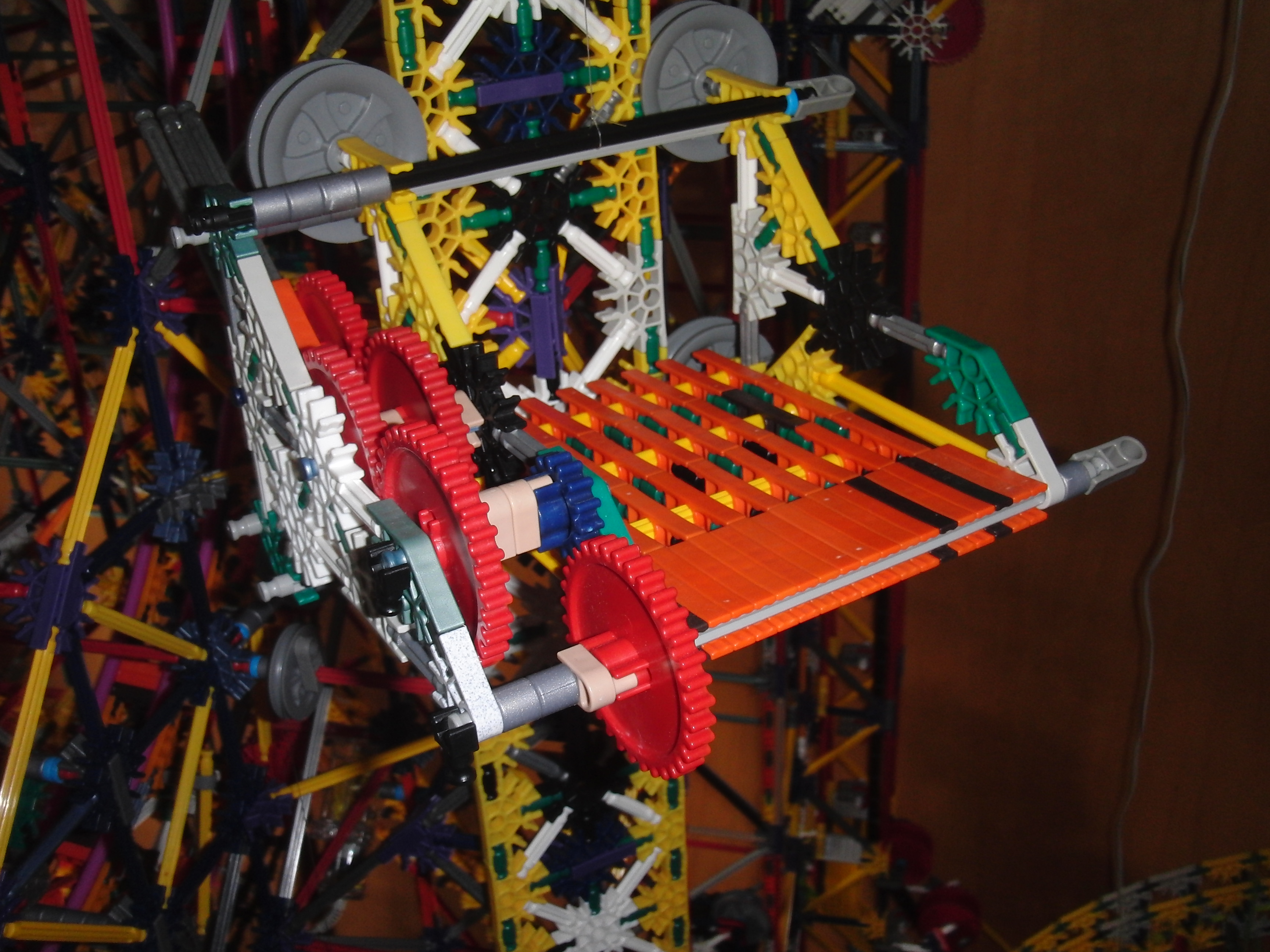

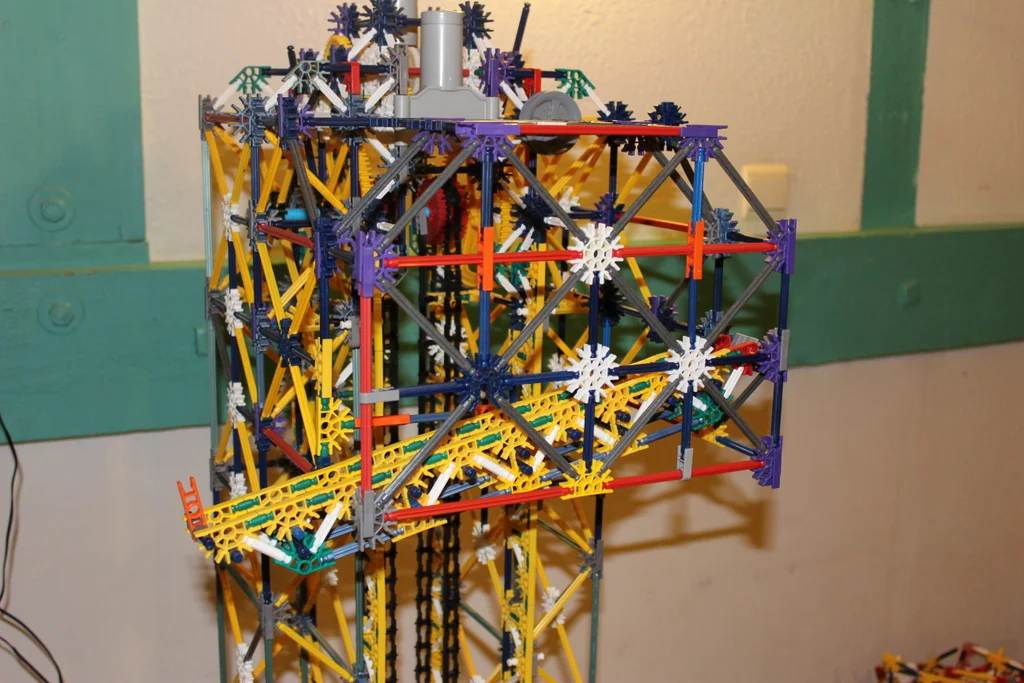

Reversing Chain Elevator Lift

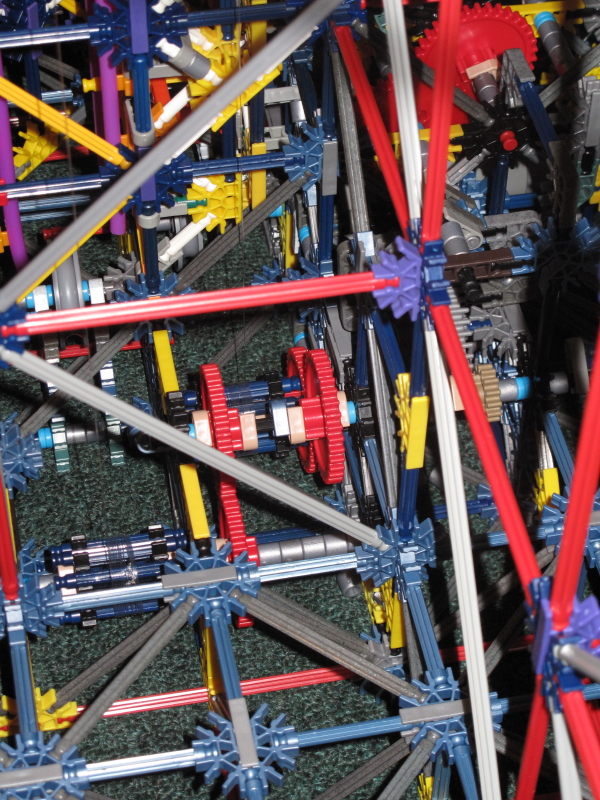

This elevator changes direction using two chains, and a bar between them is attached to a slider. The slider allows the elevator cart to stay in the same horizontal position, and the bar on the chains is free to move around a normal chain loop. This can be made to hold as many balls as you want, since all you need to do is widen the space between the two chains and modify the track length of the cart. Don’t forget to add the counterweight!

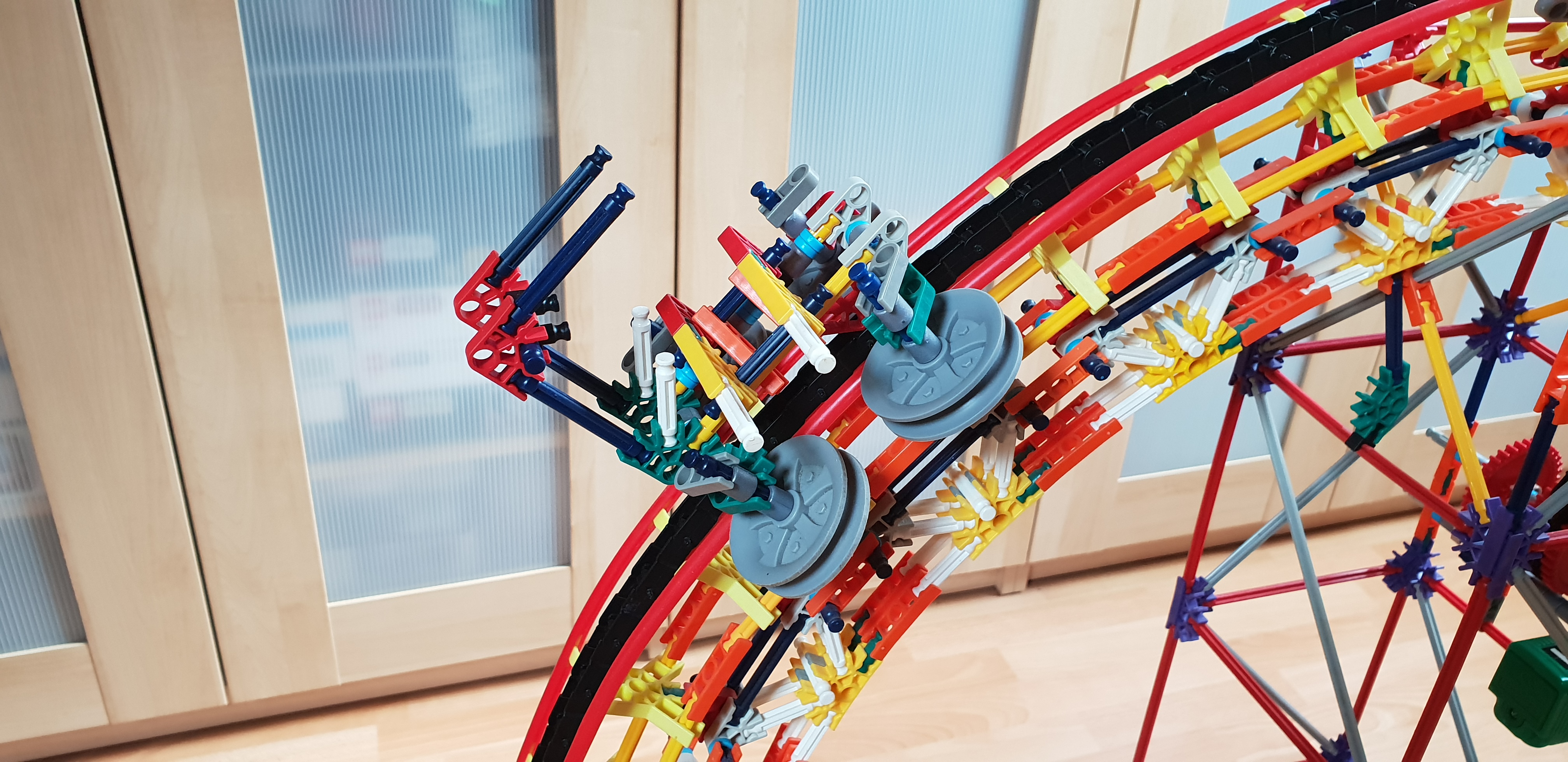

C-pulley Shuttle Lift

This is similar to the standard reversing elevator except it uses a shuttle that runs along a C-shaped track. The bar between the chains is attached to a string or chain pulley, with the other end of the string attached to the shuttle.